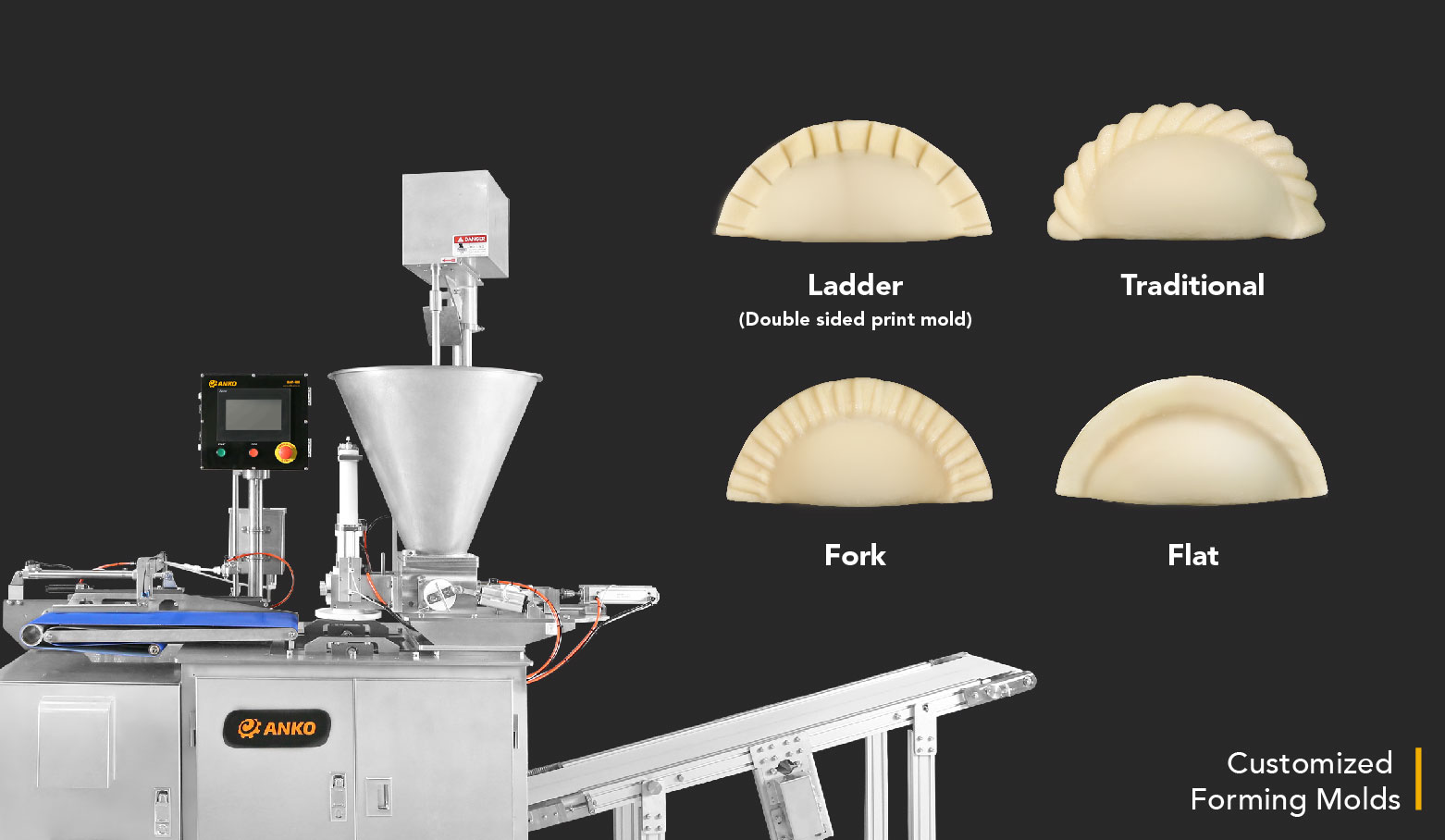

Adapted for High Oil Content Doughs to Deliver Flaky and Crumbly Pastry Textures EMP-900 | Empanada Making Machine The ANKO EMP-900 Empanada Making Machine is a filling and forming solution that produces 900 pieces of moon-shaped empanadas per hour, designed with durable food-grade materials and hygiene in mind to help food businesses efficiently standardize production at low cost while maintaining superior product quality to consistently drive business growth. Intuitive Technological Features for Efficient and Safe Production Food Branding Solutions for Efficient Product Sorting and Impeccable Product Appearance Authentic Flavors and Textures Handles high fat content dough made with an oil water solution that contributes as much as 75% of the weight of the dry ingredients to create flaky and crumbly textures to make authentic and appetizing pastries, such as Argentinian empanada, Russian chebureki, Italian calzone pie, Senegalese fataya and curry puff. ANKO’s unique filling mechanism extrudes ingredients gently to preserve the crunchy, crispy and firm textures of ingredients like corn, peas, onions, diced potatoes, olives and eggs. Better Food Product Sorting and Traditional Appearance with ANKO EMP-900 Effortless One-Stop Empanada Production with ANKO ANKO provides exclusive Empanada production planning and solutions that include the configuration of food preparation equipment, forming devices, deep fryers, packaging, and quality inspection machines. ANKO protects all machinery with plastic wrap, secures it with professional packaging materials, and then places the product in a heat-treated wooden box for shipping. This process minimizes the risk of damage during transportation. To accommodate your company's financial and timing needs clients can choose among various freight and forwarding options, including FCA, FOB, and CIF. ANKO is ISO 9001 certified, ensuring quality assurance and reasonable pricing. The machines meet all international market standards, with specifications customized to meet customer requirements. All machine parts, electronic components, and safety devices comply with CE regulations. About ANKO Food Machine Founded in Taiwan in 1978, ANKO Food Machine Company Ltd. is a leading global brand in the food machinery industry. With a presence in over 114 countries, including a North American branch and a network of 20 regional distributors, we've supported the success of over 2,500 clients around the globe. We cater a comprehensive range of solutions and services to businesses of all sizes and production levels such as restaurants, hotels, central kitchens and food factories. ANKO Offers Its Clients:

Taiwantrade.com and iDealEZ.com uses analytical cookies and other tracking technologies to offer you the best possible user experience. By using our website, you acknowledge and agree to our cookie policy.

For more information on cookies or changing your cookies settings, read Taiwantrade & iDealEZ’s Privacy Policy.